Warehousing in this multi trillion dollar, omni channel, cross-border, quick-fulfillment ecommerce landscape is difficult enough; top it with mis-shipments and lost-inventory, the multi-pronged challenges only seem to mount.

Mis-shipment basically refers to everything that can possibly go wrong with the products / packages that are all set to complete the last leg of fulfillment. Dreaded among businesses and brands as a blot in their reputation, this is one of those pitfalls that has already aggregated billions in the name of losses.

Mis-shipment basically refers to everything that can possibly go wrong with the products / packages that are all set to complete the last leg of fulfillment. Dreaded among businesses and brands as a blot in their reputation, this is one of those pitfalls that has already aggregated billions in the name of losses.

Inadvertent though, the consequences of mis-shipments are catastrophic. Imagine a customer placing an order for a black dress in size medium only to receive a printed floral overall in size extra-extra small. Or, imagine someone ordering a mixer grinder with the lid of the jars missing, or, a buyer waiting for a delivery that was supposed to arrive 3 days ago. The anger and frustration in the part of the latter stands justified.

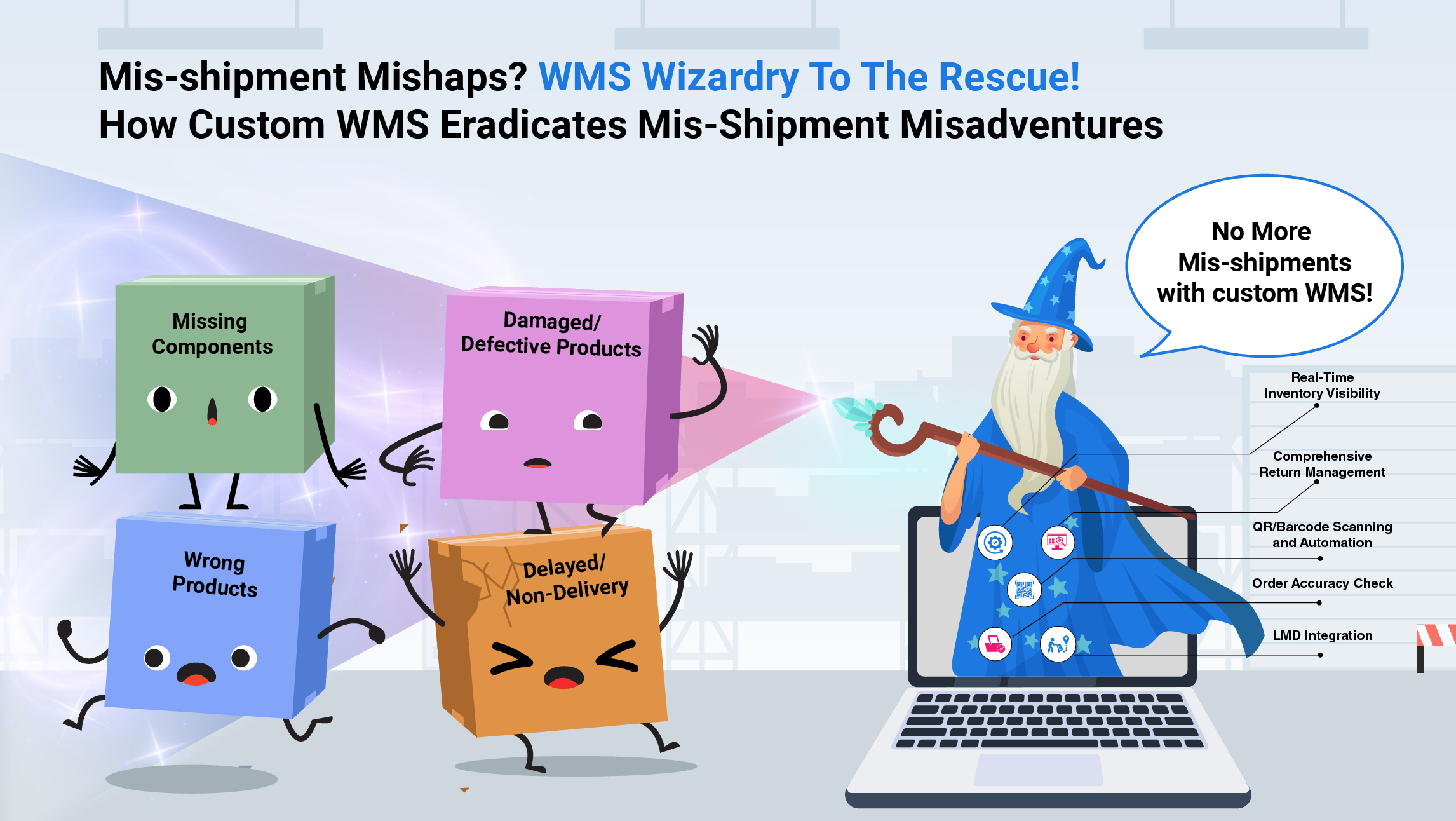

Enlisted are some of the most common examples of mis-shipment that the world of e-commerce experiences every other day –

1. Damaged / defective products :

As per statistics, damaged products account for 80.2% of product returns. While defects can be traced to the manufacturing process, most damages on the other hand, are a result of poor inventory stocking, picking, packing and manhandling during delivery.

2. Delayed / Non-delivery of package :

Over 75% customers have been affected by failed deliveries with around 16% reporting non-delivery of their packages. This usually happens because of products lost during transit, inventory and fulfillment inaccuracies and tracking / scanning anomalies.

3. Wrong products :

23% of all returns is owed to shipping wrong items. Warehousing errors, absence of proper product scanning and labeling are the main reasons behind

this rather expensive slip.

this rather expensive slip.

4. Packages with missing components :

Listed as one of the most annoying mis-shipment issues, packages with missing components or, incomplete orders happen mostly because of erroneous picking / packing, irresponsible handling / human errors or possibilities of theft during transit.

5. Missing Bucks:

5. Missing Bucks:

Cost of Mis-Shipment; A Rough Estimate Mis-shipments = Missed profits

Take for example, in case of wrong products shipped, it is the duty of the brands to bear all expenses associated with return shipping. This can cost up to $20 or more depending upon the size and weight of the concerned product. Brands will further have to bear the costs of repackaging, return processing, double pick and pack time, customer service charges and incentive coupons as well, that can bulk up the costs to a rough average of 70$ or more per mis-shipment.

Take for example, in case of wrong products shipped, it is the duty of the brands to bear all expenses associated with return shipping. This can cost up to $20 or more depending upon the size and weight of the concerned product. Brands will further have to bear the costs of repackaging, return processing, double pick and pack time, customer service charges and incentive coupons as well, that can bulk up the costs to a rough average of 70$ or more per mis-shipment.

From Minor Slips; Major Set-Backs – Consequences of Mis-Shipments on Businesses

Cost is not the only consequence of mis-shipments. The aftermath of these seemingly miniscule slips is often colossal and affects every aspect of businesses / brands that otherwise fuels its competitive competencies. Here are 4 such consequences of mis-shipments that can bring any business to its knees –

Customer Disgruntlement –

Receiving wrong / damaged items, encountering delays, non-delivery of orders and other mishaps generates smoldering reactions from customers. This dissatisfaction often translates into negative feedback, diminished customer loyalty and a decline in future patronage.

Reputation Erosion –

Mis-shipments are an inconvenience and can thus, stain a company's reputation for reliability and precision. Such errors erode customers’ trust in the business, resulting in lasting damage to its brand image and potential loss of market share.

Operational Mayhem –

Managing mis-shipments disrupts regular warehouse operations, diverting resources and manpower from essential tasks to issues that could have been avoided. This disruption can compromise overall efficiency and productivity, impacting overall supply chain and profit possibilities.

Compliance Concerns –

In certain industries, mis-shipments may trigger legal repercussions or compliance violations. Sending incorrect items, especially in regulated sectors like healthcare or pharmaceuticals, can carry significant consequences for businesses, including legal actions and regulatory fines.

How WMS Prevents Mis-Shipment Catastrophe ?

Simple automation tweaks in warehousing and a conscious detour from conventional practices with comprehensive Warehouse Management Systems (WMS) can remedy mis-shipments easily and successfully by streamlining warehouse operations and enhancing accuracy at every stage of the fulfillment process.

Simple automation tweaks in warehousing and a conscious detour from conventional practices with comprehensive Warehouse Management Systems (WMS) can remedy mis-shipments easily and successfully by streamlining warehouse operations and enhancing accuracy at every stage of the fulfillment process.

Here is a list of key WMS features that target and mitigate the core causes behind mis-shipment risks –

Real-Time Inventory Visibility –

Powered with technology like GPS, RFID and more,quality WMS can provide real-time visibility and tracking of inventory levels, location and status, ensuring that warehouse staff have accurate information when fulfilling orders. This prevents shipment delays due to product non-availability and order cancellations.

Barcode Scanning and Automation –

Wrong products shipped? Not with barcode scanning. Barcode scanning streamline order fulfillment and eliminates risks associated with manual errors. With this WMS feature, items are automatically cross-checked against customer orders, promptly identifying any discrepancies prior to shipment.

Accurate Quality Check –

Shipped a defective product? Never again, with WMS that enables Accepted quality (AQL) checks. With this feature, WMS can schedule routine inspections of incoming inventory, monitor defects and produce detailed reports, enabling real-time oversight of quality levels. In short, it prevents non-conforming products from reaching customers, thus, elimininatg possibilities of mis-shipment.

Auto Audits –

Delivered an expired product? Not with auto audits enabled by WMS. With this feature, your WMS can track expiration dates, manage stock rotation and

issue alerts for products approaching their expiration. By automating these checks, you can minimize waste, eliminate the risk of selling expired goods and boost customer trust by delivering quality at all times.

Enhanced Communication and Integration –

Integration with other business systems, such as ERP and CRM platforms, facilitates seamless communication and data exchange. This ensures that accurate order information is shared across departments, thereby reducing the risk of miscommunication and resultant mis-shipments.

LMD Integration –

LMD Integration –

Non delivery of packages? Damaged deliveries? Not with end-to-end LMD integration. Warehouse management systems can effectively integrate with the

last leg of fulfillment enabling tracking of riders and vehicles, proof of parcel delivery, e-signatures from recipients, payment integrations and more that enhances rider responsibility and reduces mis-shipment risks.

last leg of fulfillment enabling tracking of riders and vehicles, proof of parcel delivery, e-signatures from recipients, payment integrations and more that enhances rider responsibility and reduces mis-shipment risks.

Comprehensive Return Management –

Did you know; 58% shoppers expect easy returns with no questioned asked and 60% customers check return policies before making their purchase. Quick, easy and hassle free return policies can be the only saving grace in case of wrong or damaged product delivery. Comprehensive WMS can automate, expedite

and streamline the returns / refund process to prevent the trust of customers from slipping completely.

and streamline the returns / refund process to prevent the trust of customers from slipping completely.

Besides these, other WMS features like omni-channel inventory integration, real time crisis alerts, data collection and storage of information, reports and analytics, single window stock view and easy interface, cater to eliminating loopholes that pave the way for mis-shipment risks.

The WMS Promise – Shipment Beyond Blunders

It wouldn’t be wrong to say that Warehouse Management Systems are established means of conquering mis-shipping woes. However, there are many small to medium entities that find the process of choosing and integrating with the right WMS rather overwhelming. Partnering with boutique 3PL providers though, can make the task a cakewalk. Besides the benefit of cost and 24/7 availability, boutique 3PL tech developers leave ample avenues open for end-to-end

customization to ensure that every WMS is as unique as the business for which it is tailor made.

Reference:

https://www.soocial.com/

https://smiota.com/resources/

https://multichannelmerchant.

https://www.readycloud.com/

https://www.

https://smiota.com/resources/

https://multichannelmerchant.

https://www.readycloud.com/

https://www.